企(qǐ)業名稱:溫州91视频下载包裝機械有限公司

地址:浙江省瑞安市飛雲街道林泗垟工業區

銷售電話:0577-66853999

售後(hòu)電話:0577-66853998

傳真:0577-66853996

郵箱:j9@zcwybj.com

網址:www.zcwybj.com

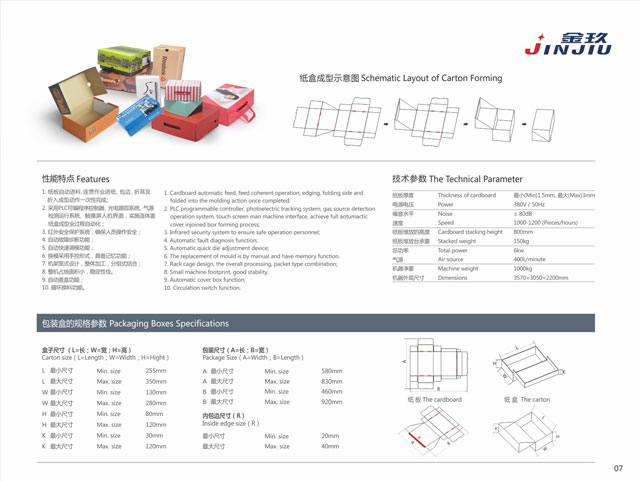

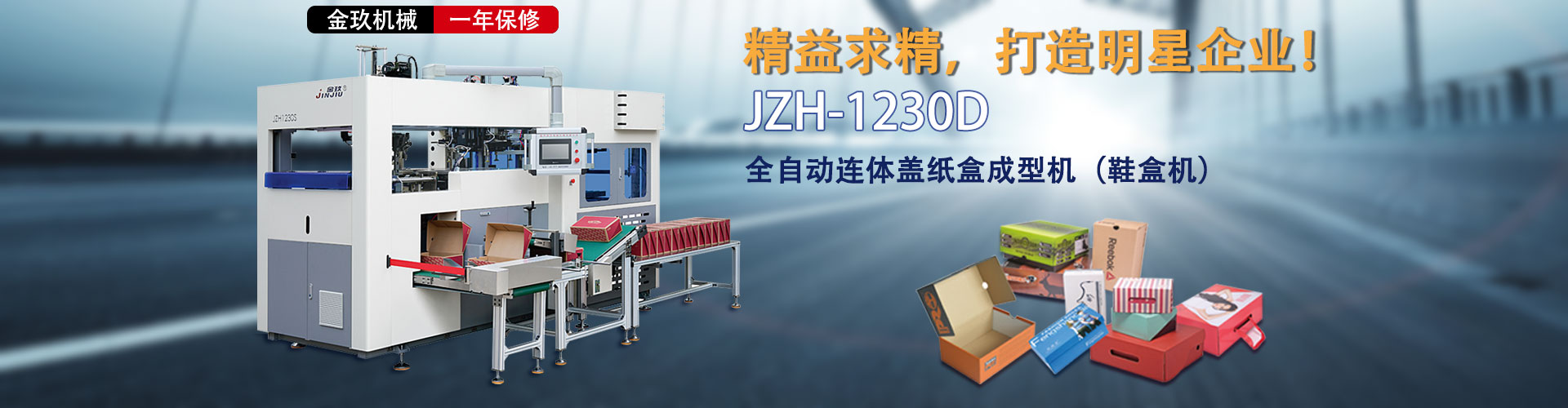

JCH-1328全自動(dòng)連(lián)體蓋(gài)紙盒成型機(鞋盒機)

Automatic Integrated Cover Paper Box Making Machine (Shoe box)

用途Usage:

該機器主要用於連體(tǐ)蓋包裝紙盒的生(shēng)產加工(gōng),廣泛應用於服裝、鞋類包裝盒;工藝品、日用品包裝盒;電子、電器包裝盒;以及五金、標準件等需(xū)要包裝的產品紙盒(hé)類(lèi)的加工製(zhì)作。

The machine is mainly used for packaging Integrated cover carton production, processing, packaging boxes are widely used in clothing and footwear; crafts, daily necessities packaging; electronics, electrical boxes; and hardware, standard parts, such as the need for packaging products manufa-cture paper boxes.

性能特點 Features:

1. 紙板(bǎn)自動進料(liào),連貫作業進紙(zhǐ)、包邊、折耳及折入成型動作一次性完成;

2. 采用PLC可編程(chéng)序控(kòng)製器、光電跟蹤係統、氣源檢測運行係統、觸(chù)摸屏人機界麵,實施連體蓋

紙(zhǐ)盒成型(xíng)全過程自動化;

3. 紅外(wài)安全保護係統(tǒng),確保(bǎo)人員操作安全(quán);

4. 自動故障診斷功能;

5. 自動快速調(diào)模功能;

6. 換模采用手控形式,具備記(jì)憶功能;

7. 機架籠式設計,整體加工,分組(zǔ)式(shì)結合;

8. 整機占地麵積小,穩定性佳。

9. 自動蓋盒功能;

10. 循環換料功能。

1. Cardboard automatic feed, feed coherent operation, edging, folding side and folded into the molding action once completed;

2. PLC programmable controller, photoelectric tracking system, gas source detection operation system, touch screen man machine interface, achieve full aotumactic cover injoined box forming process;

3. Infrared security system to ensure safe operation personnel;

4. Automatic fault diagnosis function;

5. Automatic quick die adjustment device;

6. The replacement of mould is by manual and have memory function.

7. Rack cage design, the overall processing, packet type combination;

8. Small machine footprint, good stability.

9. Automatic cover box function;

10. Circulation switch function.

技術參數The Technical Parameter

紙板厚度(dù) 電源電壓 噪音水平 速度 紙板堆放的(de)高度 紙板堆放台承(chéng)重 總功率 氣源 機器(qì)淨重 機器外觀尺寸 | Thickness of cardboard Power Noise Speed Cardboard stacking height Stacked weight Total power Air source Machine weight Dimensions | 最小(Min )1.5mm , 最大(Max)3mm 380V / 50Hz ≤ 80dB 1000-1200 (Pieces/hours) 800mm 150 kg 6kw 400L/minute 1000kg 3570×3050×2200mm |

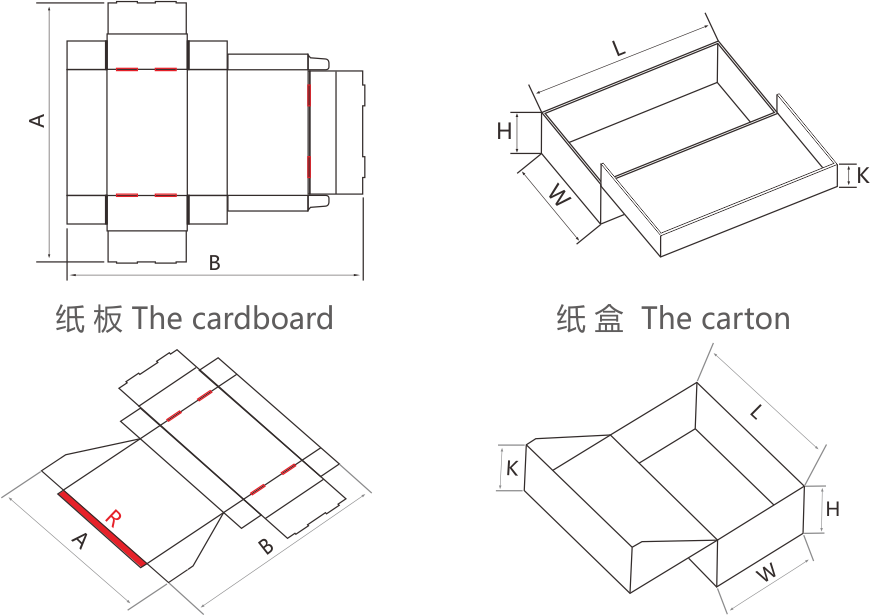

包裝盒的(de)規(guī)格參數Packaging Boxes Specifications:

盒子尺寸 (L=長;W=寬(kuān);H=高)

Carton size(L=Length;W=Width;H=Hight)

L L W W H H K K | 最小尺寸 最大尺寸 最小尺寸 最大尺寸 最小尺(chǐ)寸 最(zuì)大尺寸 最小(xiǎo)尺寸 最大尺寸 | Min. size Max. size Min. size Max. size Min. size Max. size Min. size Max. size | 255mm 350mm 130mm 280mm 80mm 120mm 30mm 120mm |

包裝尺寸(cùn)(A=長;B=寬)

Package Size(A=Width;B=Length)

A A B B | 最小尺寸 最(zuì)大尺(chǐ)寸 最小尺寸 最大尺寸 | Min. size Max. size Min. size Max. size | 580mm 830mm 460mm 920mm |

內包邊尺寸(cùn)(R)

Package Size(A=Width;B=Length)

最小尺寸 最大尺寸 | Min. size Max. size | 20mm 40mm |

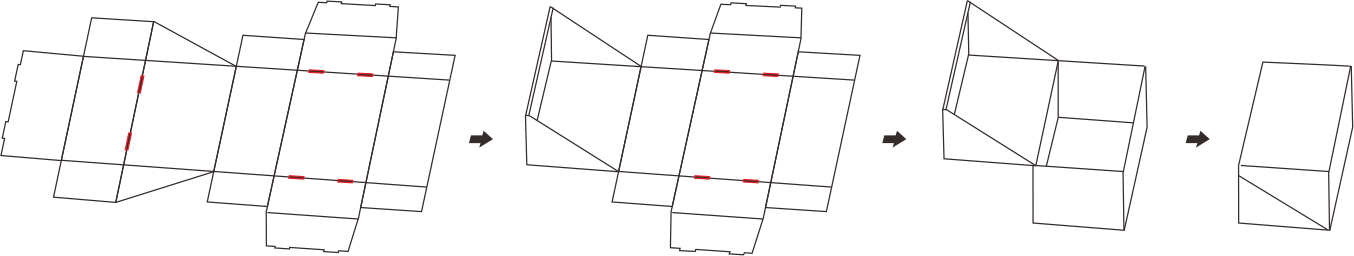

紙盒成型(xíng)示意圖Schematic Layout of Carton Forming