企業名(míng)稱:溫州91视频下载包裝機械有(yǒu)限公司

地址:浙江省瑞安市(shì)飛(fēi)雲街道林泗(sì)垟工業區

銷售電話:0577-66853999

售(shòu)後電話(huà):0577-66853998

傳真:0577-66853996

郵箱:j9@zcwybj.com

網址:www.zcwybj.com

SHOES & LEATHER - GUANGZHOU 2019

廣州(zhōu)國際鞋類、皮革及工業設備展(zhǎn)覽會

2019年5月28-31日

廣(guǎng)州·琶洲·中國進出口商品(pǐn)交易會展(zhǎn)館B區(別無分(fèn)場)

作為全球鞋業(yè)中(zhōng),具影響力的展覽(lǎn)會之一,顯輝展覽為(wéi)供貨(huò)商和專業買家(jiā)提供(gòng)一(yī)站式(shì)商貿平台,展出先進的製鞋和皮革機械、飛織、3D打印先進智能設備、各類皮革、自動化設備、化工和配件等,每年都吸引著全球的鞋業專業買手。

已(yǐ)有報名數據統計顯示:2019年,預計(jì)超過35,000名來自70個國家和地區的專業買家將(jiāng)出席此次盛事,還有13個(gè)展團,來自7個國(guó)家和地區的加持。

孟加(jiā)拉、中國、德國、香港、印度、印尼、意大利、韓國、新(xīn)西蘭、巴基斯坦、葡萄牙、西班牙、台灣、泰國(guó)、土耳其和美國16個國家和地區的700多家企業參展。

溫州91视频下载包裝機械有限公(gōng)司

溫州金(jīn)玖包裝(zhuāng)機械有限公司坐落在浙江輕工設備製造重鎮——瑞(ruì)安(ān)市,是一家專業從事包裝紙盒(hé)機(jī)械開發與製造的股份製企業。

本公司(sī)產品在(zài)吸取國(guó)內(nèi)、外同類產品的精(jīng)華基礎上;集自主研發、設計於(yú)一體。並結合用戶的(de)實際生產需求,不斷完善。其優異的性能和(hé)優良的(de)品質,優化和提升了傳統產業生產工藝;精簡節約了生產成本(běn)以及生產流程。其技術處國內領先水平;並填補了行業空白。深受廣大用戶(hù)的一致好評和青睞。

本公司成立伊始就立足於:“高起點、高品(pǐn)質、高效益”的創業宗(zōng)旨;以市場為(wéi)導向(xiàng),以振興民族品牌為己(jǐ)任;本著:“實事求(qiú)是,追求卓越,銳意進取”的企業精神。91视频下载人將堅(jiān)持:“誠信為本,質量優先,服務優先(xiān)”的經營理念(niàn)。為包裝世界提供優質、高效(xiào)的全自動(dòng)化產品而不(bú)懈努力。

Our company supplies different kinds of products. High quality and favorable price. We stick to the principle of "quality first, service first, continuous improvement and innovation to meet the customers" for the management and "zero defect, zero complaints" as the quality objective. To perfect our service, we provide the products with good quality at the reasonable price.

https://jinjiumachine.en.made-in-china.com/

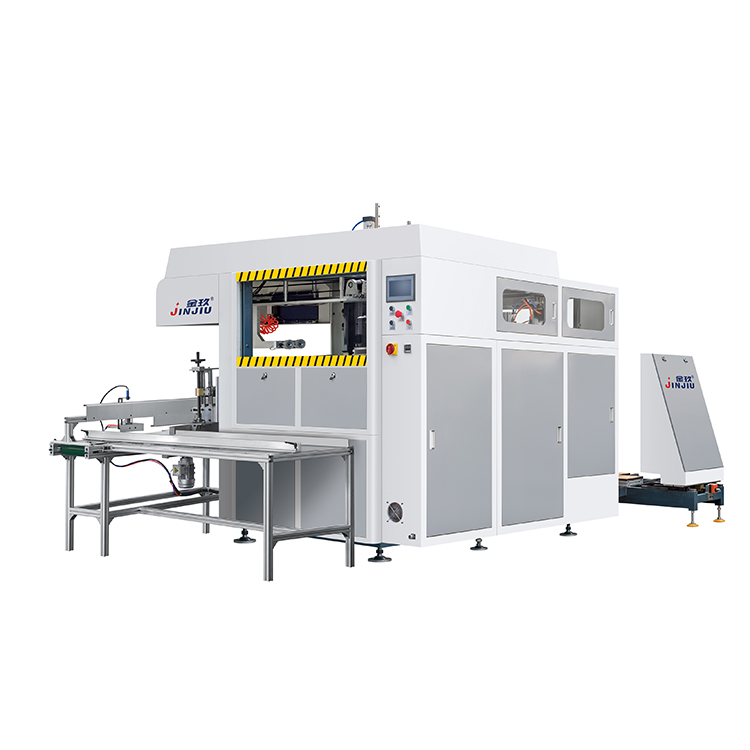

全自(zì)動高速天地蓋紙盒成型機(鞋盒機(jī))

Full Automatic Rigid Box Making Machine(Shoe/Fruit box)

JZH-8065

特性:

1、全進口智能噴膠係統,實現自(zì)動噴膠補償功能;

2、紙板自動進料,連(lián)貫作(zuò)業進紙、包邊(biān)、折耳(ěr)及(jí)折入成型(xíng)動作一次性完成;

3、采用PLC可編程序控製器、光電(diàn)跟蹤係統、氣源檢測運行係統、觸(chù)摸(mō)屏人機界麵,實施天地蓋(gài)紙(zhǐ)盒成(chéng)型全過程自動化;

4、紅外安全保護係統,確保人員操(cāo)作安(ān)全;

5、自動故障診斷功能;

6、快速換模調節(jiē)設置;

7、機架籠式(shì)設計,整體加工,分組式結合;

8、整(zhěng)機占地麵積小,穩定性佳(jiā)。

Features: 1.Imported CIGNA intelligent system for automatic glue spray compensate function; 2.Cardboard automatic feed,feed coherent operation,deging,folding side and folded into the molding action once completed; 3.PLC programmable controller,photoelectric tracking system,gas source detection operation system,touch screen man machine interface,implement the carton forming process automation; 4.Infrared security system to ensure safe operation personnel; 5.Automatic fault diagnosis function; 6.Automatic quick die adjustment device; 7.Rack cage design,the overall processing,packet type combination; 8.Small machine footprint,good stability;

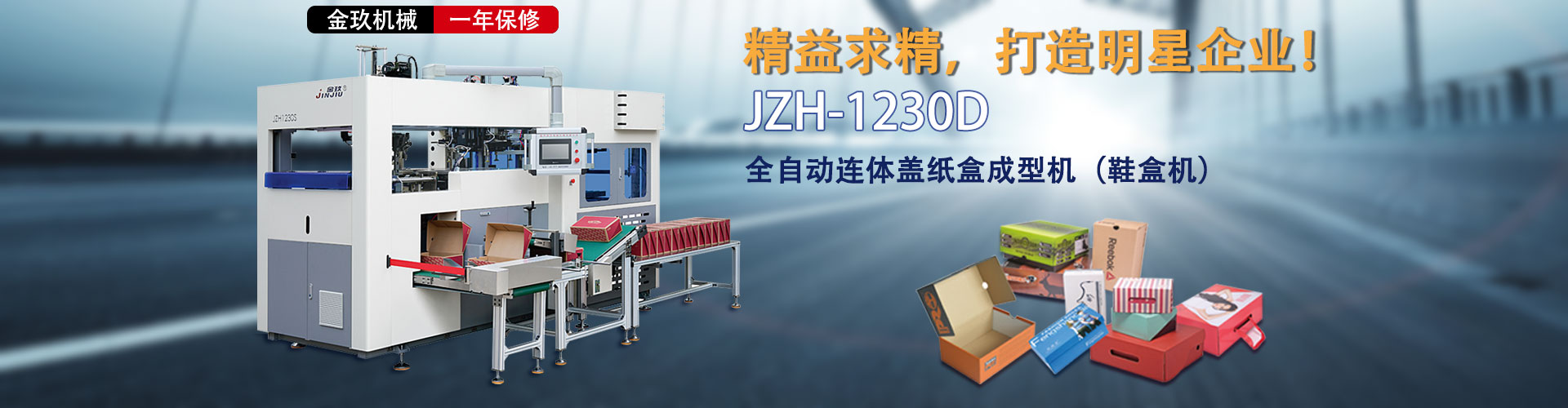

全自動高速連體蓋紙盒成型機(鞋盒機(jī))

Automatic Integrated Cover Paper Box Making Machine(Shoe box)

JZH-1228

特性:

1、采用(yòng)熱熔膠噴膠係統或水性膠噴膠係統;

2、紙(zhǐ)板自動進料(liào),連貫作(zuò)業進紙、包邊、折耳及折入成型動(dòng)作一次性完成;

3、采用運動(dòng)控製器、光電跟蹤係統、氣源檢測運行係統、觸摸屏人機界麵,實施連體蓋紙盒成型全過程自動化;

4、紅外安全(quán)保護(hù)係統,確保(bǎo)人員操作安全(quán);

5、自動故障診斷功能;

6、自動快速調模功能;

7、換模采用數控形式,速度快,具備記憶功能;

8、機架籠式設(shè)計,整體加工,分組式結合;

9、整機占地麵積小,穩定性佳;

10、自動(dòng)蓋盒功能;

11、循環換料功能;

Features:

1.The use of Thermal sol spraying system or water-based glue spraying system;

2.Cardboard automatic feed,feed coherent operation,deging,folding side and folded into the molding action once completed;

3.Adopt moving controller,photoelectric tracking system,gas supply inspect system,touch screen interface,achieve full aotumactic cover injoined box forming process;

4.Infrared security system to ensure safe operation personnel;

5.Automatic fault diagnosis function;

6.Automatic quick die adjustment device;

7.The replacement module adopts CNC system which speed is fast and with memory function;

8.Rack cage design,the overall processing,packet type combination;

9.Small machine footprint,good stability;

10.Automatic cover box function;

11.Circulation switch function;

半(bàn)自動連體蓋紙盒成型(xíng)機(鞋盒機)

Semi-automatic Integrated Cover Paper Box Making Machine(Shoe box)

JZH-1322/1828

特性:

1、采用水性膠噴膠係統

2、紙板(bǎn)自動進料,連貫作業進紙、包邊(biān)、折耳及折入成型動作(zuò)一次性(xìng)完成;

3、采用PLC可編程序控製器、光電(diàn)跟蹤(zōng)係統、氣源檢測運行(háng)係統、觸摸屏人機界麵,實施連體蓋紙(zhǐ)盒成型全過程自(zì)動化;

4、紅外安全保護係統,確保人員操作安全;

5、自動故(gù)障診斷功能;

6、快速換模(mó)調節裝置;

7、機架籠式(shì)設(shè)計,整體加工,分組式結合;

8、整機占地麵積小(xiǎo),穩定性佳(jiā);

Features:

1.The use of water-based glue spraying system;

2.Cardboard automatic feed,feed coherent operation,deging,folding side and folded into the molding action once completed;

3.PLC programmable controller,photoelectric system,gas source detection operation system,touch screen man machine interface,achieve full aotumactic cover injoined box forming pocess;

4.Infrared security system to ensure safe operation personnel;

5.Automatic fault diagnosis function;

6.Automatic quick die adjustment device;

7.Rack cage design,the overall processing,packet type combination;

8.Small machine footprint,good stability;

全自動紙盒成型機(水果(guǒ)盒機)

Automatic Paper Box Making Machine (Fruit box machine)

JZH-1000

特性(xìng):

1、進口智能噴膠係統,實現自動噴膠補償功能;

2、采用(yòng)PLC可編程序控製器、光(guāng)電跟蹤係統、氣源檢測運行係統、觸摸屏人(rén)機界麵,實施天地蓋紙(zhǐ)盒成型全過程自動化;

3、紅外安全保(bǎo)護係統,確保人員操作安全;

4、自動故障診斷功能;

5、快速換模調節裝置;

6、自動推送紙板(bǎn)前後塗(tú)膠,減少光(guāng)電眼照射紙板之誤差,塗膠更準(zhǔn)確;

7、機架籠(lóng)式設計(jì),整體加工,分組式結合;

8、整機占地麵積小,穩定性佳;

9、真空吸紙式自動進料,連貫作業進紙、折耳及折入成型動作一次性完成;

Features:

1.Imported CIGNA intelligent system for automatic glue spray compensate function;

2.PLC programmable controller,photoelectric tracking system,gas source detection operation system,touch screen man machine interface,implement the carton forming process automation;

3.Infrared security system to ensure safe operation personnel;

4.Automatic fault diganosis function;

5.Automatic quick die adjustment device;

6.Automatic push board before and after coating,reduce light magic eye irradiation error of cardboard,glue more accurately;

7.Rack cage design,the overall processing,packet type combination;

8.Small machine footprint,good stability.

9.Vacuum suction type automatic paper feeding,tandem winding into the paper folding into the forming operation is completed a one-time;

全自動紙盒(hé)成型機(水果盒機)

Automatic Paper Box Making Machine (Fruit box machine)

JZH-1600

特點:

1、進(jìn)口智能噴膠係統,實現自動(dòng)噴膠補償功能(néng);

2、采用PLC可編程序控製器、光(guāng)電跟蹤係(xì)統、氣源檢測運行係(xì)統、觸摸(mō)屏人(rén)機界(jiè)麵,實施天地蓋紙盒成型全過程自動化;

3、紅外安全保護係統,確保人員操作安全;

4、自動故障診斷功能;

5、快速換模調節裝置;

6、自(zì)動推送紙板前後塗膠,減少光電(diàn)眼照射紙板之誤差,塗膠更準確;

7、機架籠式設計,整(zhěng)體加工,分(fèn)組式結合;

8、整(zhěng)機占地麵(miàn)積小,穩定性佳(jiā);

9、真空(kōng)吸(xī)紙式自動進料,連貫作業進紙、折耳及折入成(chéng)型動作一次性完成;

Features:

1.Imported CIGNA intelligent system for automatic glue spray compensate function;

2.PLC programmable controller,photoelectric tracking system,gas source detection operation system,touch screen man machine interface,implement the carton forming process automation;

3.Infrared security system to ensure safe operation personnel;

4.Automatic fault diganosis function;

5.Automatic quick die adjustment device;

6.Automatic push board before and after coating,reduce light magic eye irradiation error of cardboard,glue more accurately;

7.Rack cage design,the overall processing,packet type combination;

8.Small machine footprint,good stability.

9.Vacuum suction type automatic paper feeding,tandem winding into the paper folding into the forming operation is completed a one-time;